When you are manufacturing furniture and home décor in Indonesia, it is critical to take every precaution to assure your product quality. More importantly, you must ensure that your products are safe – not damaged and not defective – during the shipment.

As an importer, you should never rely on your supplier to take the extra step to protect your products with appropriate packaging unless you have clearly asked about it at first. Many suppliers believe that once a shipment leaves their factory, they are no longer responsible for any issues that arise during shipping and handling.

So how can you ensure the packaging of your products is good enough to secure the product inside? The answer may be simpler than you think.

Conducting a carton drop test is one of the best and most effective ways to ensure your packaging meets your quality standards and protects your product inside. It is important to ensure that your carton packaging can withstand being dropped multiple times and from different angles.

Here are 5 things you need to know about carton drop tests.

ISTA 1A as an International Standards for Drop Tests

The International Safe Transit Association (ISTA) is “an organization focused on the specific concerns of transport packaging.”

The international standard for carton drop tests is called ISTA 1A. It specifies approved procedures for a variety of testing, including vertical shock tests, alternative incline tests, alternative horizontal tests, and, of course, carton drop tests.

Drop Test Height is Depend on the Carton Weight

You might be wondering what height the carton should be dropped from. The weight of a carton is used to calculate drop height. A box weighing less than 21 pounds (10 kilograms) will be dropped from a height of 30 inches (760 mm), whereas a carton weighing 100 pounds (45 kilograms) will be dropped from a height of 8 inches (200 mm). So, it is depending on the carton weight.

Cartons are Dropped 10 Times During the Test

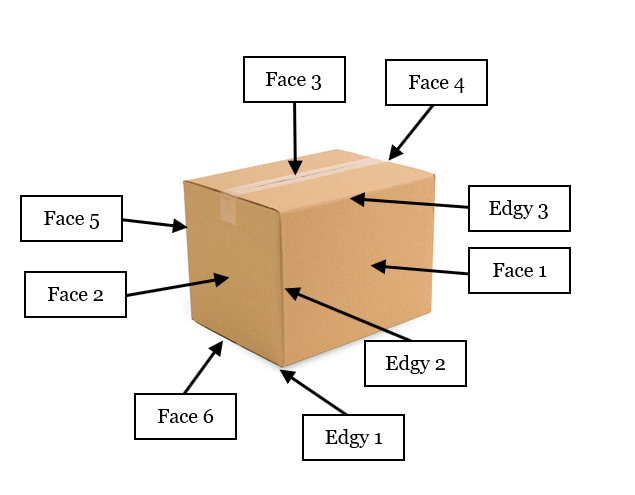

During the drop test, the carton is dropped 10 times; on its corners, three of its edges, and six of its faces during a drop test. The faces, edges, and corners are identified in the diagram below.

After the Drop Test, Your Carton is Opened to Determine a Pass or Fail Result

After being dropped, the quality inspector will open the carton packaging to see whether the product inside is safe or broken. If any of the following conditions are met, means that the drop test is failed.

- Damage to the export carton

- Damage to the product packages inside

- Scratches, dents, or other product damage

- Products that do not function as expected

If your packaging failed the test, it means that they are not strong enough.

Drop Tests Can be Done as Part of Your Pre-Shipment Inspection

A carton drop test is usually performed in the pre-shipment inspection as this is your final opportunity to take corrective actions before your production is finished and packed, and before you settle the balance payment. By doing so, you can be more confident that your products will arrive in your warehouse undamaged.

For more information about Carton Drop Test in Indonesia, you contact us here today.